You must normally bleed compressed air traces right before connecting them to the ATX device. This will take out any water and Filth Which might be in it (see methodology Guidelines for use of the ATX).

In combination, This provides off a way more uniform complete. These glass beads are a hundred% recyclable which makes it a cost-productive process.

Your safety is essential to us. Videos proven are filmed inside of a managed ecosystem for illustrative applications only.

The full procedure occurs in a compartment often called a bead blasting cabinet. This cupboard allows to prevent the operator from getting exposed to fragments of blast media flying from the machined element.

All through dry ice blasting, contaminants are removed from the surface area within an productive and managed fashion. Here is a specific and concise rationalization of what transpires to contaminants:

Nitrofreeze® cryogenic deburring supplies makers and machine retailers with a better way to remove burrs from small plastic pieces. Burrs, » Browse More

Drying: Thoroughly dry the substrate to prevent the formation of water places or surface defects during the powder coating. Air drying, oven drying, or forced air drying can be utilized, according to the substrate and facility’s capabilities.

These glass beads are successful at cleansing, deburring and peening metallic surface. The glass beads are spherical in form and when influence the area produce a micro-dimple.

You no more have to choose between damp blasting or dry abrasive blasting since the Dustless Blaster can perform the two. But how can you notify which approach to blasting is finest to your task? Let’s go around some particular aspects that is likely to make the proper preference very clear.

When considering spray programs focus on adaptability likewise and pick kinds with flexible configurations, as they offer overall flexibility to cater to various coating prerequisites.

Exactly what is Galvanization? November 5, 2019 No Reviews Galvanizing is known as the entire process of implementing a protective coating to steel or iron. The coating is crafted from zinc and is applied to

Stripping surfaces always involves severe ability. But Are you aware there are greater, safer, and more productive ways to work than working with conventional sandblasting?

A soda blaster can be a form of sandblaster that click here uses soda in place of h2o to develop an environmentally friendly blasting knowledge. Soda, just like the baking filler sodium bicarbonate (baking soda), is Just about the most normally made use of abrasives in blasting.

This creates an anchor pattern around the element's surface area, substantially bettering the adhesion in the powder coating for the substrate. Numerous different types of abrasives are available, as well as their use relies on the sort of end and contaminant to get removed. For illustration, Walnut shells might be useful for de-burring whilst plastic grit will probably be made use of to eliminate paint. In the same way, glass beads are most well-liked if the end goal is to obtain a matte and satin end.

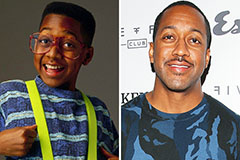

Jaleel White Then & Now!

Jaleel White Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Batista Then & Now!

Batista Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!